The Standard for In-Plant Transport

"Designed for confined, low overhead clearance applications for handling loads too big or heavy for forklifts and most cranes."

Moving Loads 10-50 Tons, In Tight Spaces, Can Be Daunting

You know the problem. You have items upwards of 40 tons that need to be moved from this room in your facility to another but you’re confronted with a host of challenges including tight spaces, various floor conditions, and finding something that can handle that amount of weight. You ask, “How is it possible to move loads this heavy in the typical congested manufacturing environments without tearing up equipment and factory floors?”

OmniTruck Was Built For This

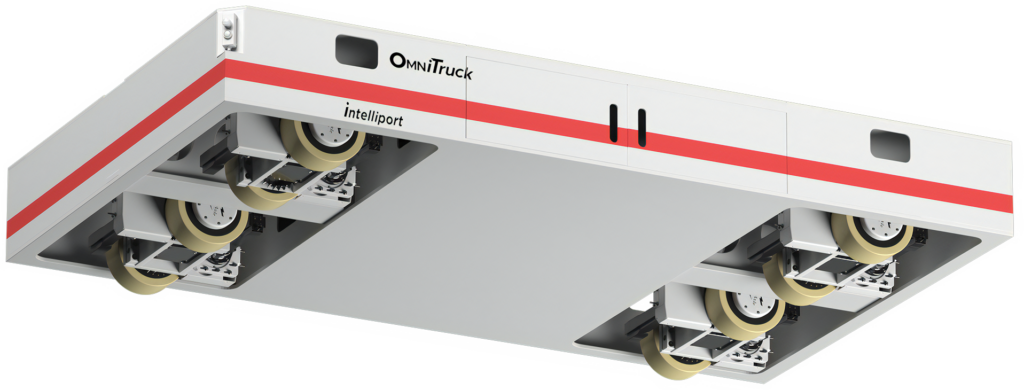

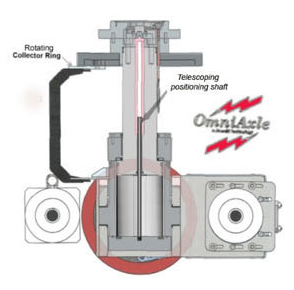

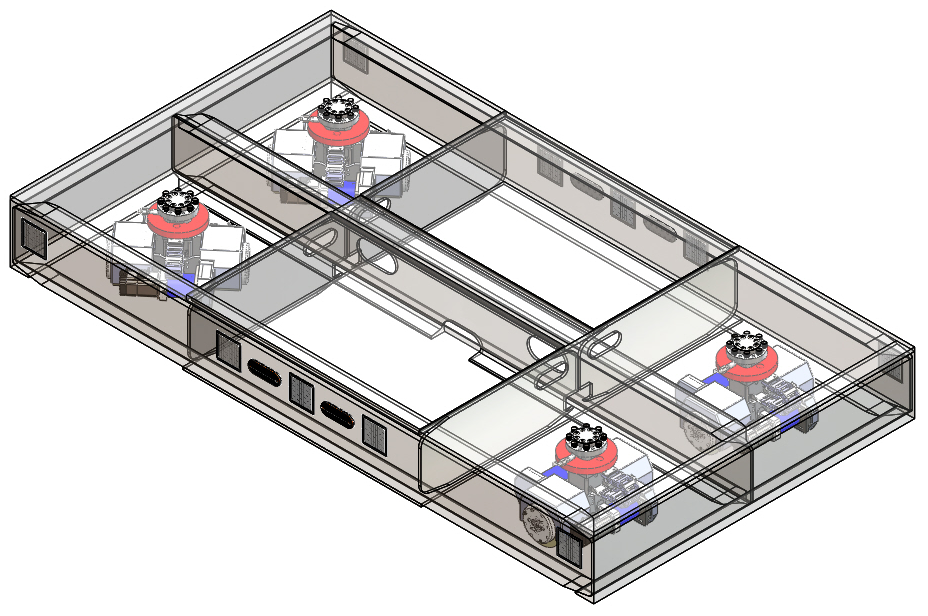

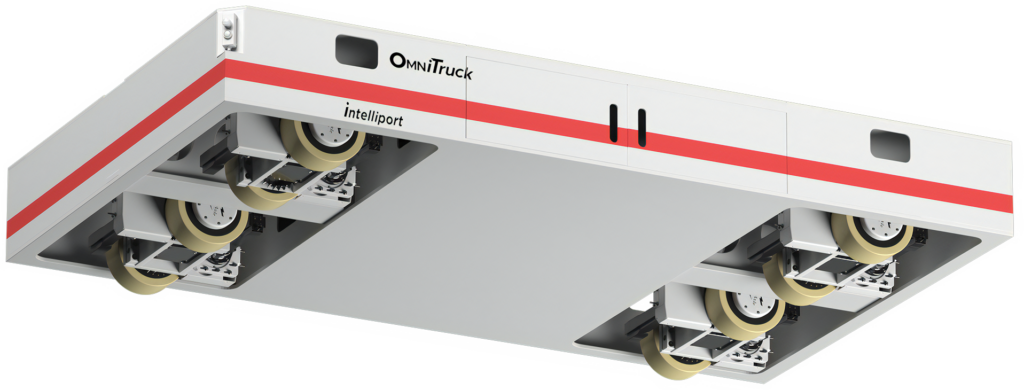

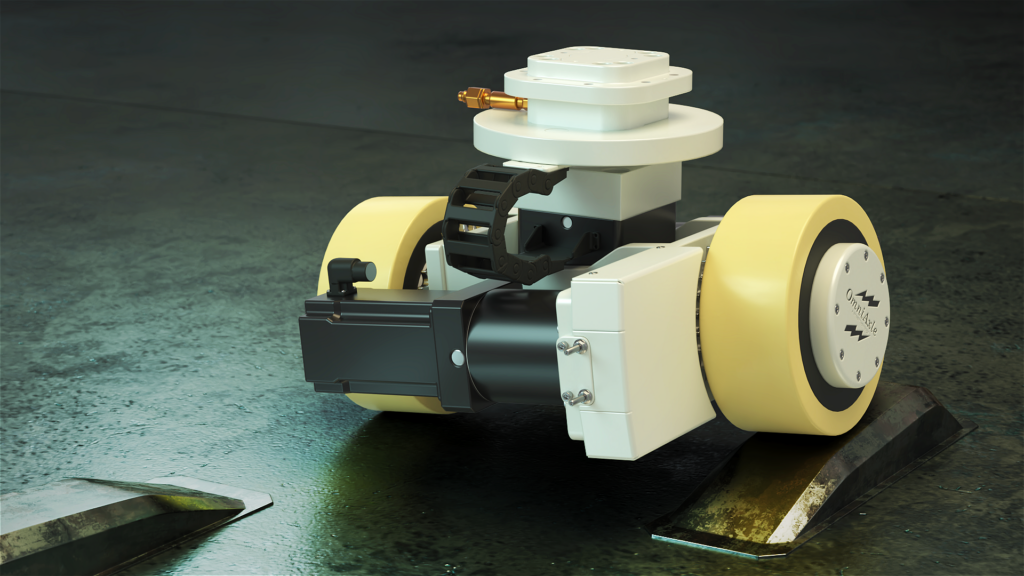

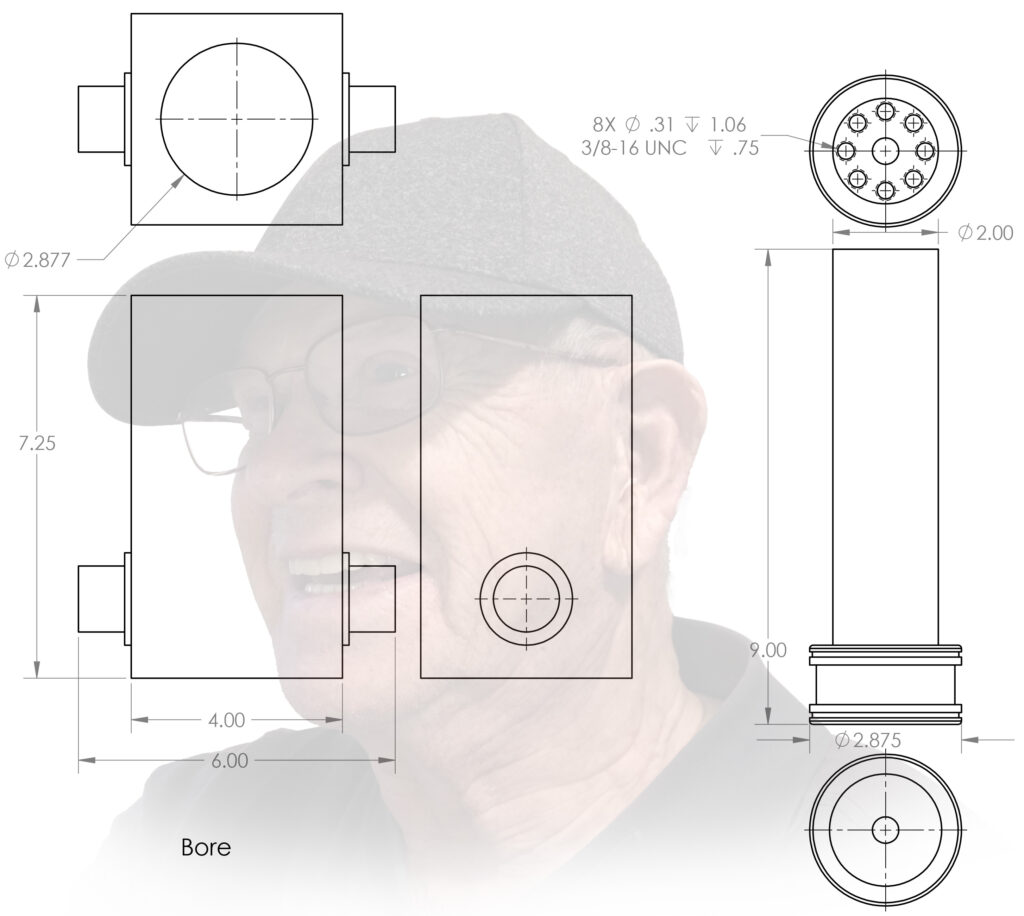

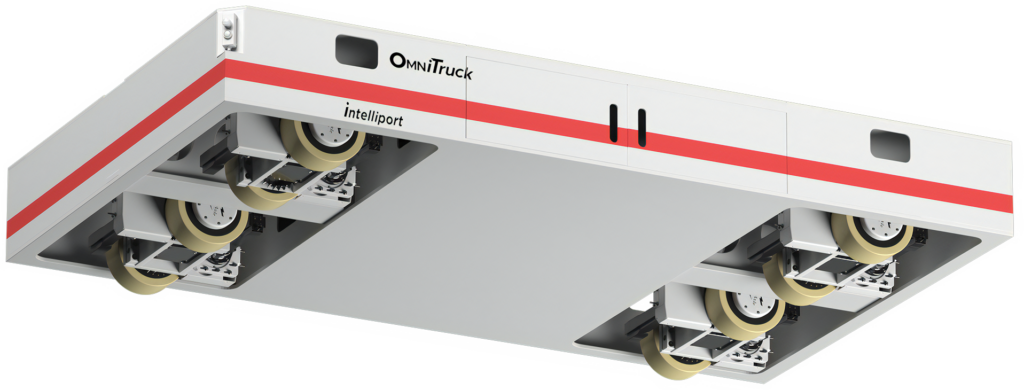

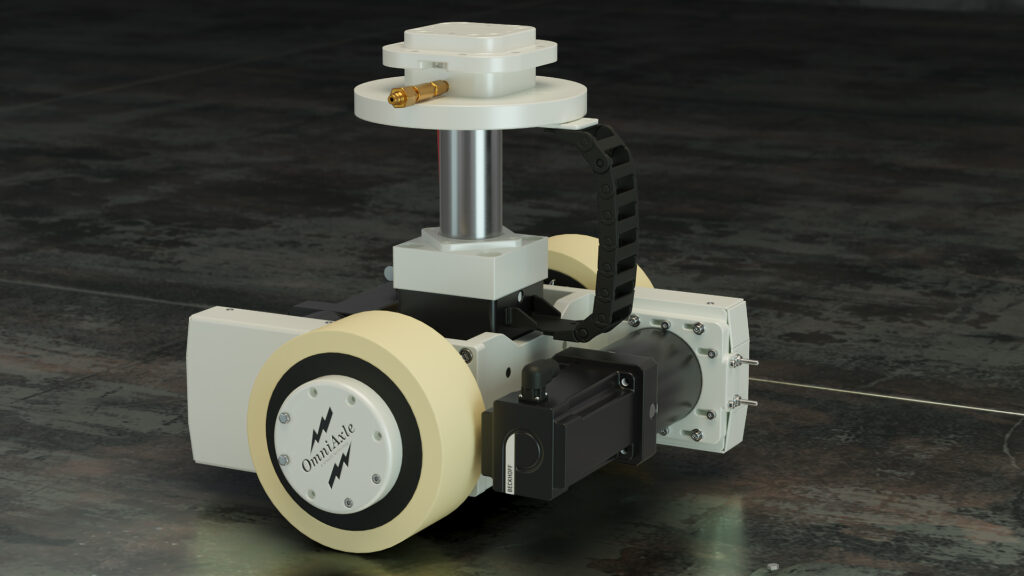

Say hello to the OmniTruck with its patented UNILOAD – Fluid Equalizing Suspension, a truly unique solution to this very problem. The technology consists of multi-axle load carrying platforms (In plant transporters). From 3 to 20, on-center rotating, vertical lifting axle assemblies that equalize the weight distribution across every lift point regardless of floor conditions. We call this the OmniTruck. Our OmniTruck in plant (IP) transporters are designed to lower down and drive underneath stand-supported loads. When in position, they lift the loads clear off the floor and drive in ANY direction. The fluid equalizing suspension guarantees that every tire is carrying only its share of the load without ever creating overload conditions on the floor.

Now With a Broader Reach

The OmniTruck concept is the second generation of ultra-heavy capacity, INPLANT Self-Propelled Modular Transporters (IP-SPMT). It was designed for confined, low overhead clearance applications for handling loads too big or heavy for forklifts and most cranes. The previous generation of this technology has revolutionized how companies precision-move payloads of 50-tons through 250-tons with great precision and dexterity. This new smaller generation of OmniTruck heavy in-plant transporters are targeting a much broader market of similar applications ranging from 10-ton to 50-tons, in addition to pursuing those same ultra-heavy applications in ranges 50 to 250-tons and beyond.

Similar, Not The Same

While the European style big multi-axle modular transporters (SPMTs) used in construction are common across a wide variety of heavy rigging applications, those platforms are large and travel on truck tires. They are just too big for indoor applications. They require considerable open space to operate. The OmniTruck technology is a patented miniaturized version, designed to operate in the confined, low overhead clearance plant applications for handling loads too big or heavy for forklifts and most cranes.

The Ideal Facility

The technology really comes into its own in plants like Solar Turbines in San Diego and NASA’s big rocket motor assembly facility near New Orleans. These are typical examples of plants that historically build large products.

With time, those types of plants likely find themselves with the need to build their own “next generation” products. They outgrow their existing spaces and are forced to consider building new plants or do major modifications to their existing buildings to accommodate heavier cranes and greater door and overhead clearances.

Save Millions

The low-profile, OmniTruck transporters can save millions of dollars in construction costs, by the customer being able to continue in the current plant without modifications. Other examples are the abilities to use the transporters for precision positioning and alignment in major assembly operations.

Automatically Guided

OmniTruck transporters have sophisticated control systems to accommodate their omni-directional travel and self-loading capabilities. This makes them an ideal base platform as automatic guided vehicles (AGVs) of virtually unlimited capacities. The same automation benefits attached to small AGV operations are now totally obtainable in ultra-heavy capacities.

Nearly Any Type of Floor

A unique feature of these OmniTrucks is their ability to operate on almost any type of floor or roadbed. Uneven terrain is a major benefit of their inherent equalizing suspension system. They operate on deteriorated floors, handle steep ramps, asphalt roadbeds running between buildings, and can go almost anywhere in and around a plant. Poor floors are welcome.

Features and Benefits

- Equalized Weight Distribution: Every wheel bears equally on the floor – always.

- Floor Damage Totally Eliminated: Can cross thresholds, floor drains, cracked and broken floors, as well as steep ramps without incident.

- Multiple Steering Options: It can drive forward/aft, left/right, spin on its axis or turn on any point.

- Self-Loading: The OmniTrucks can drive under raised load platforms, then lift and move through highly congested areas effortlessly.

- Precision Positioning: The OmniTruck can effortlessly make movements in the X, Y and Z motions measured in thousandths of an inch.

- Heavy AGV Applications: Ten, twenty, fifty tons and beyond.

- Ideal For Narrow Aisles: transfers between crane bays, and low overhead clearances make them ideal for difficult manufacturing spaces.

About Intelliport

Intelliport Corporation is the licensing entity for the creative works of its founder Mel Terry. Following a distinguished career in heavy rigging applications with high pressure industrial air cushion equipment throughout the 70s and 80s, where he was moving oil rigs in Prudhoe Bay, Alaska, weighing well over 400 tons, and creating ship side launch systems for both Todd (SEA) and Vancouver Shipyards (BC) weighing over 4,000 tons per move. The 4,000-ton ship launch applications used one hundred and four, 48” diameter fluid film bearings, rated at 40-ton capacity each. It was from the latter that the first generation of equalizing suspension axle assemblies were first conceived. The ability to lift the 600 ft long BC ferries and slide them out onto ship launch skids with every one of those fluid film bearings carrying ONLY its share of that massive load.

That triggered the concept of designing wheeled axle assemblies that, just like the fluid film bearing, could lift a load to the point of floatation and then be free to move in any direction over uneven surfaces. These axle assemblies were, and still are, totally unique for the in-door/in-plant handling environments.

Broader Range of Application

Now comes the next generation of technology innovations. New concepts in both axle and transporter equalizing suspension systems address a much broader range of application potential, in the far greater arena of industries that are regularly dealing with fabrication and assembly operations with load weights of 10 through 40 tons.

OmniTruck’s Multiple Configurations

The new series of OmniTruck transporter designs offer at least six new transporter equalizing suspension configurations over the previous versions. Until now every transporter had to be furnished with ALL of the sophistication needed for the most complex applications. For customers that didn’t need, or want, all of those unique capabilities, cost saving configurations were just not available. That is no longer the case. OmniTruck transporters can now be furnished with only the amount of sophistication needed for the particular application. From Tricycle suspension, four to twenty axle transporters, Plank configurations, 3+1 suspension, AGVs, Towable trailers, manual and fully automatic controls, and more.

Contact Us for Additional Information

Contact us at [email protected]. We are looking forward to answering your questions and providing additional information you may request. Feel free to provide a detailed description of your inquiry and we will try our best to respond as soon as possible.