Suspension Capabilities

View the OMNiTruck’s capabilities in action in the video above.

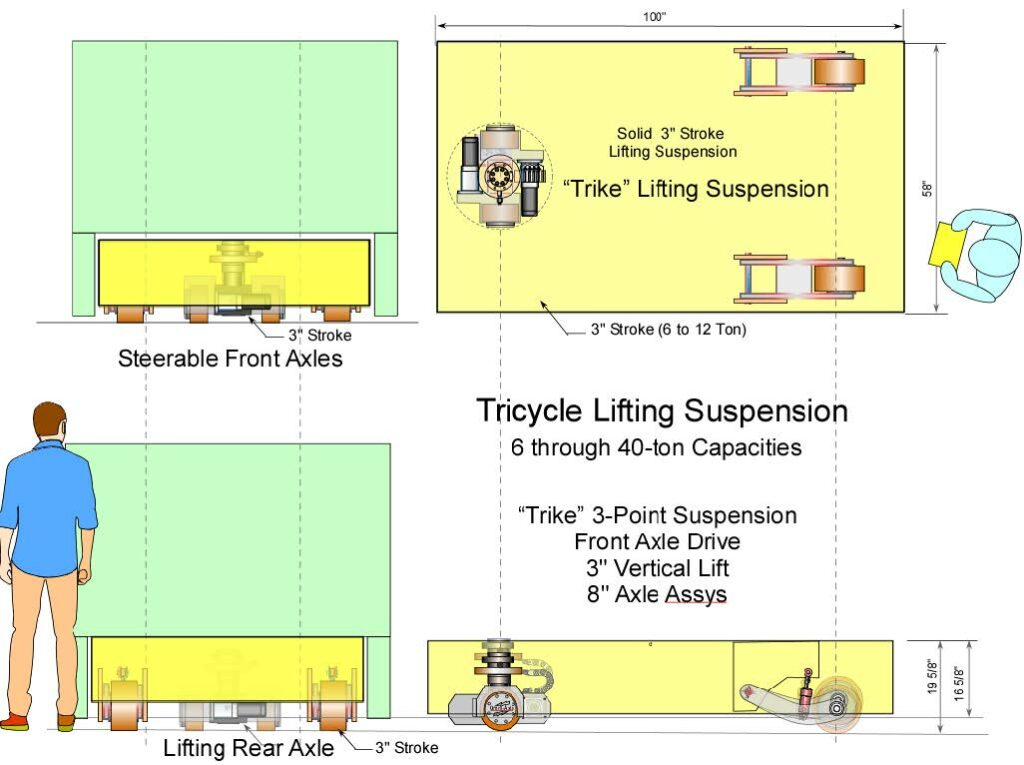

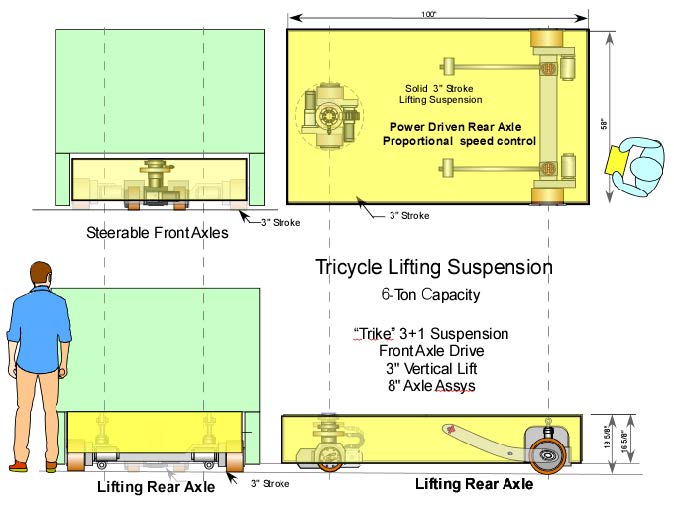

Tricycle Lifting Suspension

Tricycle Lifting Suspension

In its simplest form, the Tricycle Lift Suspension transporter will have two otherwise fixed hydraulically lifting, load carrying wheel assemblies at the rear of the transporter. At the front of the transporter frame is one full-function Omni-Axle that lifts and is programed to steer on a radius drawn from the center of either of the rear wheels when turning to the left or right. In this configuration, the programing can be made to provide precise lift heights if needed.

Tricycle Lifting Suspension

With Driven Rear Axles

In another version of the Tricycle Lift Suspension transporter. They can have two otherwise fixed hydraulically lifting, load carrying power driven wheel assemblies at the rear of the transporter. At the front of the transporter frame is one or a pair of full-function Omni-Axles that lift and are programed to steer on a radius drawn from the center of either of the rear wheels when turning to the left or right.

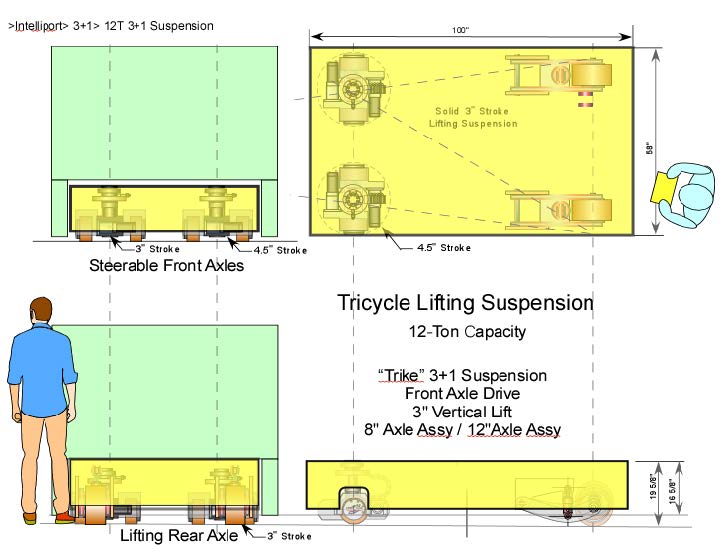

Tricycle 3+1 Lifting Suspension

Tricycle 3+1 Lifting Suspension

Here is our “3+1” Tricycle Lifting Suspension. What that means is that once the transporter is driven under a stand supported load, the two rear lifting load carrying wheel assemblies and one forward OmniAxle all lift to the top of their stoke, forming a solid 3-points of suspension. The second OmniAxle lifts to essentially the same height but has freedom to extend and retract as the transporter moves over irregular surfaces, floor drains, ramps, etc. All four of the wheel assemblies see only their design share of the load, essentially regardless of the load CG or the variations of the floor.

The control system dictates that the two OmniAxles work together as a single point to provide the same steering function as the previous slide.

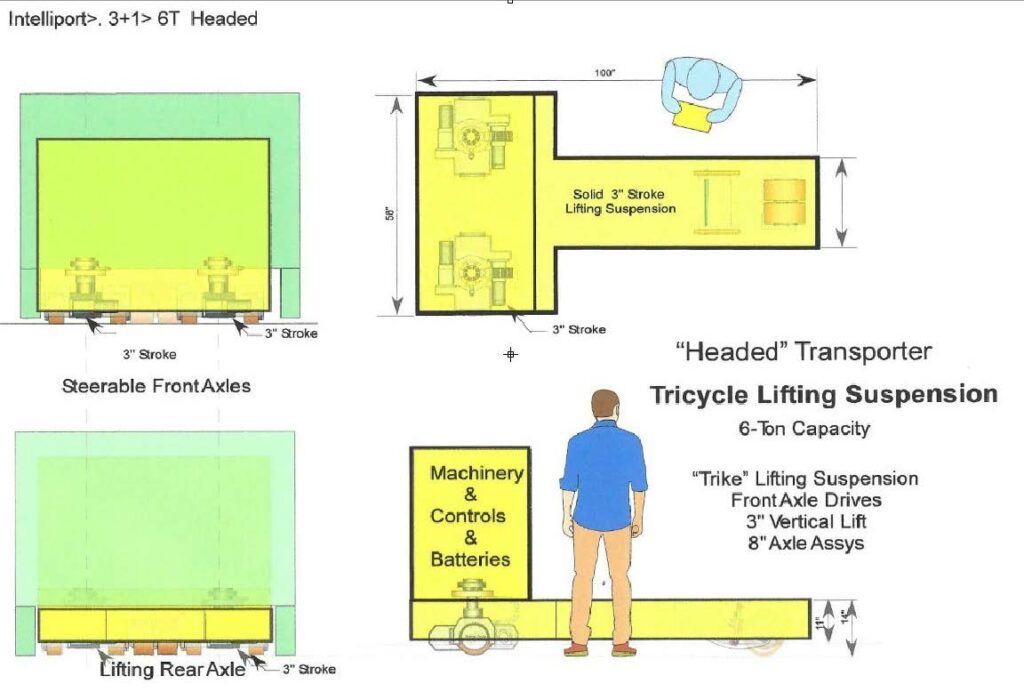

Specialty "Headed" Tricycle Lifting Suspension

Specialty "Headed" Tricycle Lifting Suspension

For certain specialty applications were there may be limited access under the intended load. Or it may be the transporter must have the lowest possible interface height to accommodate low overhead beams or doorways that otherwise might need to be replaced. This is an illustration of “Headed” transporter. Which means the transporter’s batteries, controls, and other components are in a raised enclosure at the front of the transporter.

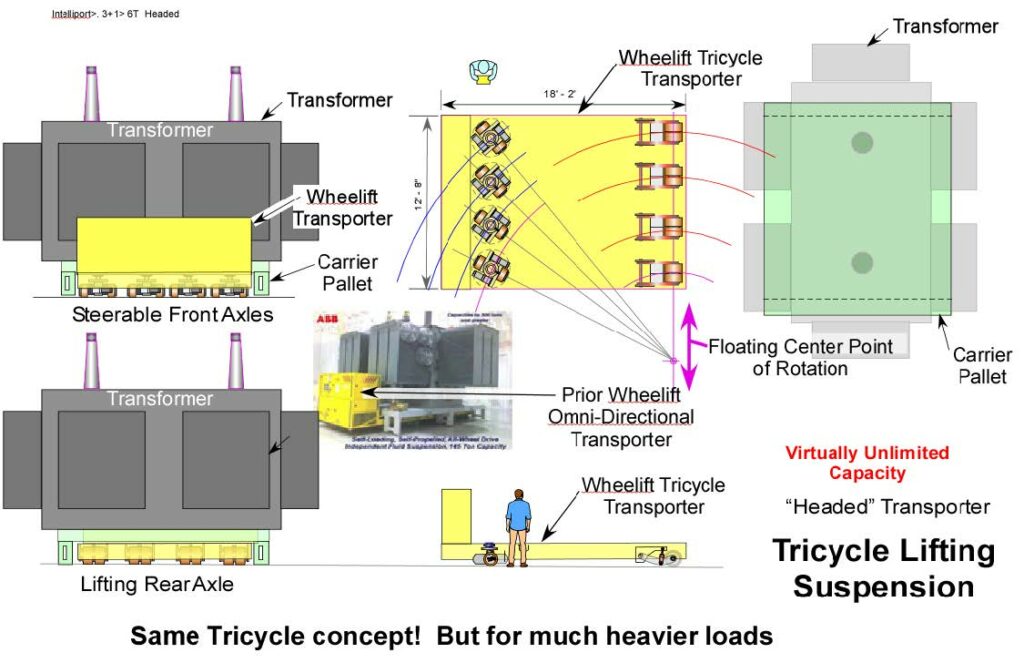

For Heavier Loads

Specialty "Headed" Tricycle Lifting Suspension

Tricycle Lifting, But For Heavier Loads

Tricycle Suspension provides virtually unlimited design and application opportunities. Designs can scale up to accommodate a wide range of customer application. The degree of control sophistication can be tailored to fit the customer’s needs without unnecessary added costs.

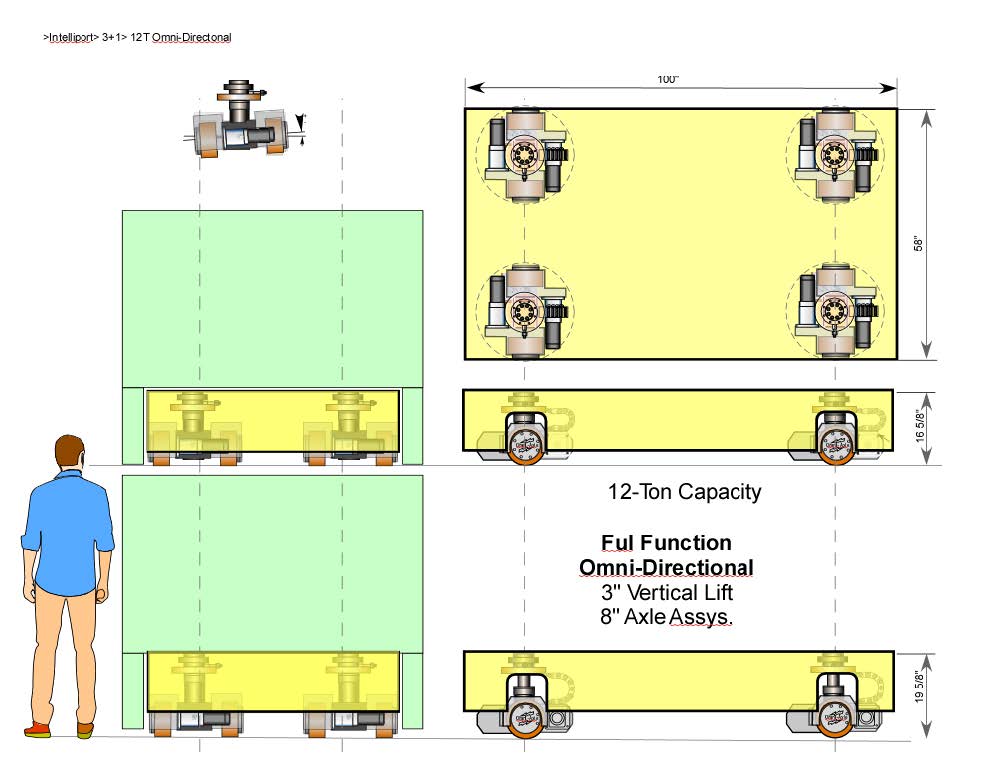

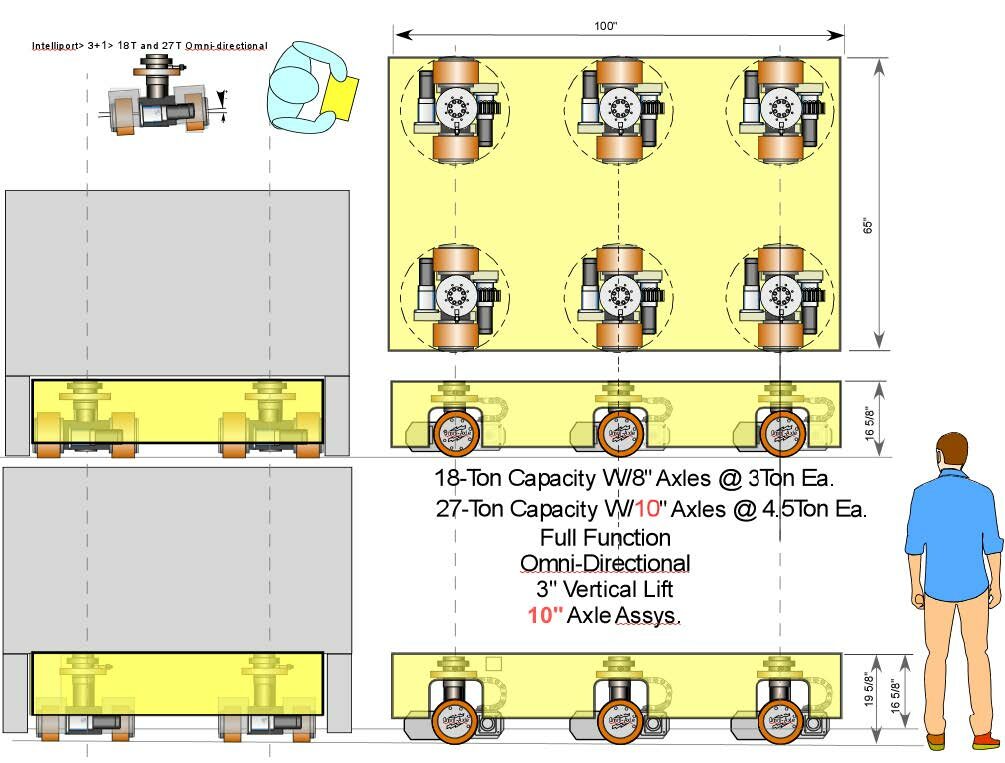

Fully Functional Omni-Directional Travel

Fully Functional Omni-Directional Travel

In this case the transporters have four or more full-function OmniAxles. In their simplest form, they can be programmed for 3+1 suspension or can have fully controllable lift. The transporter is fully omni-directional. In this configuration, the transporter is ideally suited for interfaces that require precision placement as close as +/- .002”. The transporter can be programmed for precision lift and travel. And is ideally suited for automatic guide vehicle applications in virtually unlimited carrying capacities.

Fully Functional Omni-Directional Travel

Scalable Capabilities

Transporters can be increased in length and/or width to accommodate additional capacities. The interior space for control components is a governing factor. With the dimensions shown, the same deck height transporter can be fitted with 3-ton or 4.5- ton Omni-Axles to ac ate load and space requirements.

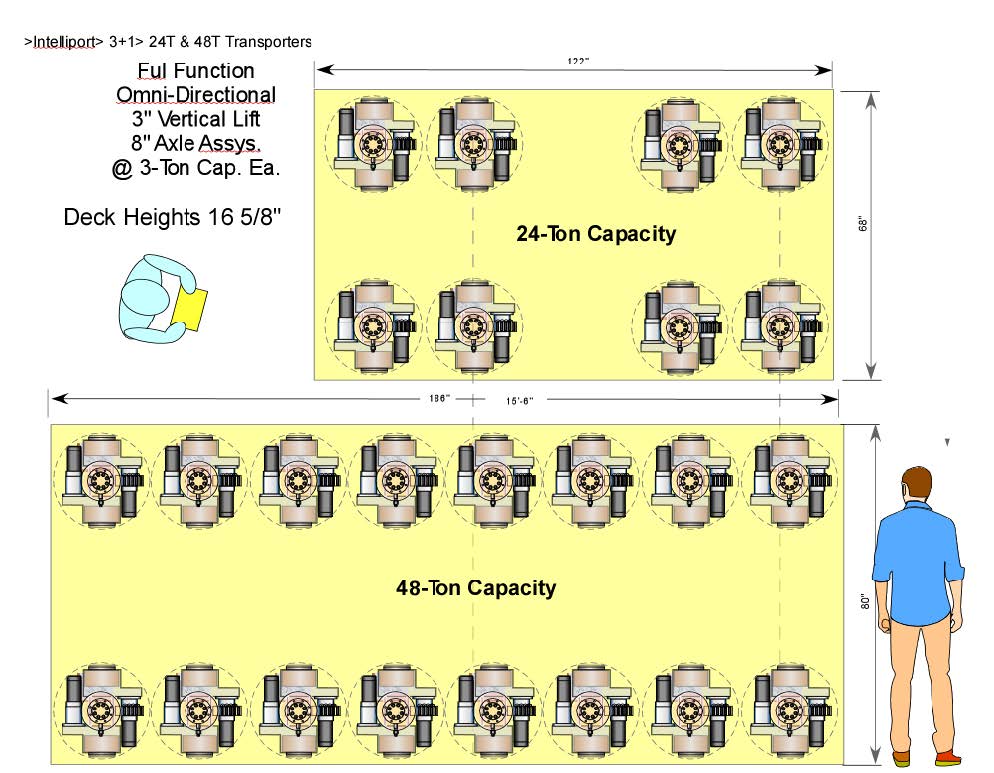

Multiple Axle Assemblies

Multiple Axle Assemblies

This slide is an illustration of the design versatility that can be applied to meet specific plant and load requirements. In these configurations the transporters are fully self-loading and omni-directional.

These configurations can be designed for the badly deteriorated site conditions, such as severely uneven floors, ramps, aprons between buildings, etc.

Contact Us for Additional Information

Contact us at [email protected]. We are looking forward to answering your questions and providing additional information you may request. Feel free to provide a detailed description of your inquiry and we will try our best to respond as soon as possible.